-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

Mitsubishi 65 Times Reinforcing Mesh Welding Machine

| Place of Origin | China |

|---|---|

| Brand Name | DIXUN |

| Certification | CE |

| Model Number | DX-GWC-2500A |

| Minimum Order Quantity | One set |

| Packaging Details | The reinforcing mesh panel welding machine is nude packing. Put into one 40 feet container. |

| Delivery Time | 25 working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 10 sets per month |

| Product Name | Reinforcing Mesh Welding Machine | Width Of Mesh Panel | Max 3300mm |

|---|---|---|---|

| Mesh Size | From 100*100mm To 300*300mm | Wire Diameter | 5-12mm |

| Control System | Panasonic PLC And Touch Screen | Power Transformer | 300KVA |

| Labor Cost | Two Workers | Warranty Period | 18 Months Since The Machine Is Installed In Buyer's Factory |

| Voltage | 380V/220/415V/440V | Welding Speed | 45-65 Times Per Min |

| Highlight | Thyristor synchronous Reinforcing Mesh Welding Machine,Mitsubishi Reinforcing Mesh Welding Machine,3300mm mesh panel welding machine |

||

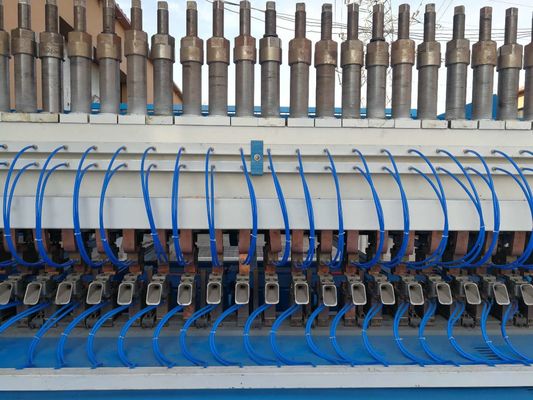

Mitsubishi PLC Strong Machine Structure Rebar Welded Mesh Welding Machine

Rebar Welded Mesh Welding Machine Introduction:

Rebar Welded Mesh Welding Machine is also called concrete reinforcing mesh welding machine, BRC mesh welding machine. The rebar welded mesh welding machine is used to produce reinforcing mesh. The rebar welded mesh welding machine adopts power electronic synchronous control technology, welding time and separate control welding are managed by automatic control system, human-machine interface, intelligent operation, humanization.

Rebar Welded Mesh Welding Machine Features:

1. The rebar welded mesh welding machine control system Panasonic PLC control system, combined with Weinview touch screen, can directly input and display equipment operating parameters, intelligent and easy to operate.

2. Cross wire hopper: the stepper motor drives the disk-type device to automatically drop wires, and the hopper has a large capacity of storing wires max up to 1.5 tons. When there is no wire in the hopper, the rebar welded mesh welding machine will stop running automatically.

3. Line wire feeding mechanism: Mitsubishi servo motor is equipped with planetary reducer to drive pneumatic compression wire feeding device to send diameter wire to the welding position. The equipment is automatically welded.

4. Mesh pulling mechanism: Mitsubishi servo motor supporting planetary reducer drives pneumatic clamping mesh pulling device to ensure the stability of the system and the standard size of the welded mesh.Automatic reciprocating mesh drawing can realize the production of lengthening size mesh.

5. Water-cooled welding electrodes and a new type of special transformer for water-cooled welding mesh with epoxy resin are adopted, which is smaller in size and higher in safety and reliability than traditional transformers.

6. Low-voltage electrical appliances are made of Schneider, Tianzheng, Mingwei and other well-known brands to ensure the efficient and stable operation of the equipment.

7. The rebar welded mesh welding machine will stop working automatically if there is no cross wires in hopper device.

8. When there is malfunction on the machine, the PLC will alarm, which is convenient to adjust the machine.

9. The cross wire space adjustment adopts PLC micro-computer control, set on the touch screen.

10. The mesh pulling system in cycle is automatically calculated, no need manual setting. The mesh pulling car can be back to origin automatically after finishing the pulling.

Rebar Welded Mesh Welding Machine Technical Parameetrs:

| Model | DX-GWC-2500A | DX-GWC-3000A | DX-GWC-3300A |

| Width of mesh | 2500mm | 3000mm | 3300mm |

| Line wire space | 100-300mm(adjustable) | 100-300mm(adjustable) | 100-300mm(adjustable) |

| Cross wire space | 100-300mm(adjustable) | 100-300mm(adjustable) | 100-300mm(adjustable) |

| Wire diameter | 5-12mm | 5-12mm | 5-12mm |

| Welding electrodes | 24PCS | 30PCS | 32PCS |

| Welding transformer | 160KVA*12PCS | 160KVA*15PCS | 160KVA*16PCS |

| Welding press type | Mechanical | Mechanical | Mechanical |

| Industrial voltage | 220V/380V/415V/440V | 220V/380V/415V/440V | 220V/380V/415V/440V |

| Welding way | Thyristor synchronous control | Thyristor synchronous control | Thyristor synchtonous control |

| Line wire type | Pre-cut | Pre-cut | Pre-cut |

| Cross wire type | pre-cut | Pre-cut | Pre-cut |

| Welding speed | 40-65 times per min | 40-65 times per min | 40-65 times per min |

| Overall dimension | 40m*4.2m*2.3m | 40m*4.7m*2.3m | 40m*5.2m*2.3m |

| Total weight | 11T | 13T | 15T |

| Labor required | 2 workers | 2 workers | 2 workers |

Rebar Welded Mesh Welding Machine Applications:

Rebar welded mesh has been widely used in the construction industry, in addition to the production of precast reinforced concrete components, more is used in the cast-in-place concrete structural members: construction: multi-storey and high-rise industrial and civil housing construction (foundation, floor, floor, roof, wall, etc.);Transportation: concrete pavement of expressway, soft base section, bridge deck pavement, anti-crack of bridge pier surface, concrete ground of toll plaza, railway platform, station square and cargo concrete ground, concrete ground of airport runway, freight yard and square, tunnel lining, wharf and port, etc.;Municipal construction: overhead overpass surface pavement, square concrete ground, concrete pipe, fence, slope protection, etc.Water conservancy and electric power coal: water conservancy facilities, electric dam foundation, protective net, etc.;Others: flood control facilities, slope reinforcement, collapse protection, breeding industry, animal husbandry, etc.

Rebar Welded Mesh Welding Machine Packing:

![]()

Rebar Welded Mesh Welding Machine Photos:

![]()

![]()

![]()

![]()