-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

Width 2.5m 12mm Welding Reinforcing Mesh Machine Panasonic Control System

| Product Name | Reinforcing Mesh Welding Machine | Wire Diameter | 5-12mm |

|---|---|---|---|

| Voltage | 380V/220V/415V/440V | Welding Speed | 40--65 Times Per Min |

| Rated Capacity | 150kva*12pcs | Mesh Width | 2500mm |

| Mesh Length | 3-12 Meter | Control System | Panasonic PLC |

| Line Wire Space | 100-250mm | Cross Wire Space | 100-250mm |

| Number Of Welding Electrode | 24pcs | ||

| Highlight | width 2.5m reinforcing mesh machine,12mm reinforcing mesh machine,panasonic control reinforcing mesh welding machine |

||

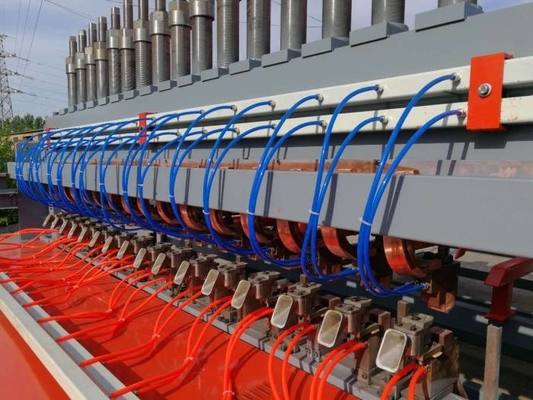

Machine Weight 9 Tons Mesh Width 2.5m Reinforcing Mesh Welding Machine

Reinforcing Mesh Welding Machine Introduction:

This is our new type reinforcing mesh welding machine DX-GWCD-2500, which adopts spring to control welding, the welding speed can be up to max.70 times/min. We can also supply other types of wire mesh welding machines 5-12mm and 3-8mm.

Reinforcing Mesh Welding Machine Features:

1. Control system:Japan Panasonic intelligent PLC

2. Touch screen: Weiview(Taiwan).

3. Low-voltage apparatus :Schneider(France). Variable-frequency drive:Delta(Taiwan)

4. Brake clutch motor connect the pricipal axis directely, stronger power.(Special technology)

5. Cross wire feeding: Step hopper. Longitude wire feeding:Manually(or equipted with a wire feeding car).

6. Mesh pulling:Panasonic(Japan) servo motor,great power and precision.

7. Transformer cooling:Water cooling. Electrodes cooling: Water cooling, very efficient.

8. Longitude wire sending Servo motor (1.5kw) and planetary reducer for sending longitude wires when welding, can save time.

9. Cross wire feeding. The cross wire feeder will be specially designed; it can bear 1 ton wires, much more than before.

10. Brake motor&helical gear reducer. The principal axis connects brake motor&helical gear reducer directly, strong power, high stable.

11. Welding transformers 12 pcs cast water-cooling transformers, high efficiency. The welding degree is adjusted by PLC.

Reinforcing Mesh Welding Machine Technical Parameters:

| No. | Item | Specification |

| 1 | Welding Wire Diameter | Φ5.0-12.0(mm) |

| 2 | Cross Wire Space | 100-250mm(adjustable) |

| 3 | Line Wire Space | 100-250mm(adjustable) |

| 4 | Max Mesh Width | 2500mm |

| 5 | Max mesh length | 1.0-12.0m |

| 6 | Number of Electrodes | 24 pcs |

| 7 | Welding Speed | 0-70times/min |

| 8 | Rated Voltage | Three phase,380V,50HZ |

| 9 | Rated Power | 200KWA*12(Water cooling system) |

| 11 | Main Motor | 15KW (Electromagnetic Brake Motor) |

| 12 | Line Wire Feeding | Pre-cut Wires,Sending on the down welding electrodes automatically |

| 13 | Cross Wire Feeding | Pre-cut Wires,Automatic Feed from Pre-loading Hopper |

| 14 | Line Wire Space Adjustment | Manually |

| 15 | Cross Wire Space Adjustment | Set by Touch Screen |

| 16 | Material | Carbon Content ≤0.2%,Round Steel Bars and Ribbed Steel Bars and Galvanized Steel Bars with Tensile Strength ≤650MPa |

| 17 | Welding Time | 10ms-100ms |

| 18 | Pulling Mesh Way | CNC with Servo motor |

| 19 | Welding Way | By Control Silicon Control Electric Resistance Weld |

| 20 | Finished Mesh | Automatic Fall and Automatic Output |

| 21 | Pressure Mode | Adjustable Spring Pressure,Driven by Motor |

| 22 | Weight | About 9 Tons |

| 23 | Overall Dimension | 13.5*3.7*2.2m |

Photos of Reinforcing Mesh Welding Machine:

![]()

![]()

![]()