-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

Hole Size 150*150mm Plc Reinforcing Mesh Welding Machine For Steel Bar

Contact me for free samples and coupons.

WhatsAPP:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Reinforced Steel Bar Mesh Welding Machine | Steel Bar Diameter | 5.0-12.0mm |

|---|---|---|---|

| Width Of Mesh | 2500mm | Number Of Electrode | 24pcs |

| Line Wire Space | 100-300mm | Cross Wire Space | 100-300mm |

| Length Of Mesh | Max. 12m | Rated Capacity | 150kva*12pcs |

| Main Motor | 18.5kw | Welding Speed | 45-65 Times Per Min |

| Machine Weight | 9.0 Tons | Machine Dimension | 14*3.7*2.2m |

| Floor Space | 25*10m | Labor Cost | 2 Workers |

| Highlight | 150*150mm reinforcing mesh welding machine,steel bar reinforcing mesh welding machine,plc reinforcing mesh machine |

||

Hole Size 150*150mm PLC Reinforced Steel Bar Mesh Welding Machine

Reinforced Steel Bar Mesh Welding Machine Introduction:

This Machine is mainly used to produce steel wire diameter 5.0-12.0mm,material round steel wires and ribbed steel wires,mesh size:100*100-300*300mm reinforcing mesh panels.

Reinforced Steel Bar Mesh Welding Machine Features:

Line Wires Aligning and Automatic Feed Device

The Line Wires Automatic Feeding Device is to automatically send the manually threaded line wires to the welding electrode position of the main mesh welding machine, so as to facilitate the main mesh welding machine to complete the welding process. When the line wires feeding car is automatically feeding, the next group of line wires will be manually prepared, which can realize the production of the main mesh welding machine without shutdown and greatly improve the production efficiency.

Line Wires Aligning and Automatic Feeding Device

The Line Wires Automatic Feeding Device is to automatically send the manually threaded line wires to the welding electrode position of the main mesh welding machine, so as to facilitate the main mesh welding machine to complete the welding process. When the line wires feeding car is automatically feeding, the next group of line wires will be manually prepared, which can realize the production of the main mesh welding machine without shutdown and greatly improve the production efficiency.

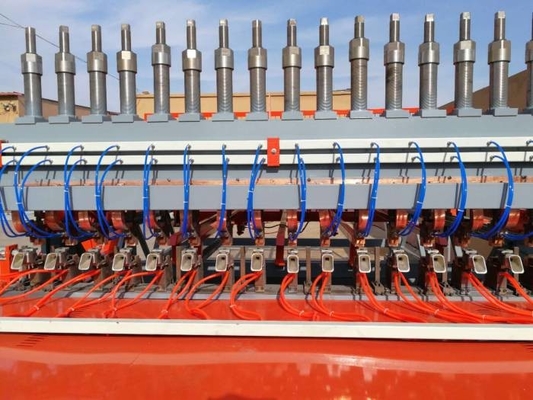

Welding electrode

The up and down electrodes all adopts special CuCrZr,the electricity conductivity,hardness and wear resistance are all very good,the changeover time of the longitudinal cell is reduced to about 30 seconds.Welding electrodes are driven by the spindle passing through the crank,and installed with adjustable spring pressure,This structure is not affected by climate and convenient maintenance and usage.

And the up and down electrodes both adopt water cooling system,thus an reduce the heat of the upper and lower electrodes when the machine works, and can work for 24 hours continuously.

Pulling Mesh Device

It is to pull the welded cross wires out of the mesh according to the parameters set by the program, and according to the length of the mesh, it can realize multiple reciprocating pulling mesh, until the whole mesh is completely pulled out.

It is composed of four parts: the bottom frame, the movable pulling mesh frame, thepulling mesh car and the supporting mesh tubes.

Reinforced Steel Bar Mesh Welding Machine Technical Parameters:

|

Material

|

Cold and hot rolled low carbon steel wire

|

|

Max. mesh width (cross wire length)

|

2500 [mm]

|

|

Min. mesh width (cross wire length)

|

1500 [mm]

|

|

Max. mesh length (line wire length)

|

6000 [mm]( According to the customer request)

|

|

Min. mesh length (line wire length)

|

1500 [mm]

|

|

Line wire spacing

|

≥100 [mm], adjustable

|

|

Cross wire spacing

|

≥100[mm], programmable adjustable

|

|

Line wire diameter

|

Φ6- Φ12 [mm]

|

|

Cross wire diameter

|

Φ6 - Φ12 [mm]

|

|

Max. welding capacity

|

Φ12+ Φ12 [mm]

|

|

Max. welding speed

|

40 - 60 [strokes/min] (cross wire no°/min)

|

|

Air consumption

|

≥0.6Mpa, 1.5m 3/min

|

|

Electronic parts specifications:

|

|

|

Numbers of welding transformer

|

12

|

|

Numbers of electrode

|

24 |

|

Power supply voltage

|

380 [V] - 50 [Hz] (According to customer request)

|

|

Total installed power

|

150 [KVA]*12

|

Photos of Reinforced Steel Bar Mesh Welding Machine:

![]()

![]()

![]()

![]()