-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

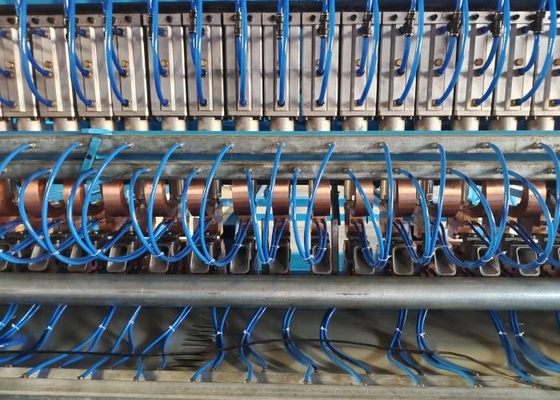

Transformer 200KVA Reinforced Steel Bar Mesh Panel Welding Machine PLC

| Place of Origin | China |

|---|---|

| Brand Name | DIXUN |

| Certification | CE |

| Model Number | DX-GWC3000B |

| Minimum Order Quantity | One set |

| Packaging Details | . The bracket and auxiliary equipment will be with plastic package, spare parts and mold in wooden box. 2. The main machine will be fixed in the container by steel wire rope to make it stable. 3. It needs 1x40'GP container for shipment. |

| Delivery Time | 30 working days |

| Supply Ability | 3 sets per month |

| Product Name | Reinforced Steel Bar Mesh Panel Welding Machine | Width Of Mesh Panel | 3000mm |

|---|---|---|---|

| Line Wire Space | 100-250mm | Cross Wire Space | 100-250mm |

| Length Of Mesh Panel | 3-12m | Number Of Electrode | 30pcs |

| Welding Speed | 80 Times Per Min | Welding Pressure | Air Cylinder |

| Line Wire Type | Pre-cut | Cross Wire Type | Pre-cut |

| Machine Weight | 10T | Machine Dimension | 9500*3800*2200mm |

| Highlight | Reinforced Mesh Panel Welding Machine,Steel Bar Mesh Panel Welding Machine,200KVA Reinforcing Mesh Welding Machine |

||

Transformer 200KVA PLC Reinforced Steel Bar Mesh Panel Welding Machine

Introduction of Reinforced Steel Bar Mesh Panel Welding Machine:

This is our new developed pneumatic reinforcing steel bar mesh panel welding machine . The welding speed can be up to maximum 80 times/min.It has advantage of easier machine maintenance, less machine problem, easier to learn and operate, save power and consumption, less welding spark etc.

1.This line adopt special welding process ,Efficient water cooling system and precision welding control system and high quality copper alloy electrodes with unique appearance.

2.The line wire and the weft wire of wire mesh welding machine are pre-straight and pre-cut.

3.The line wire is feeding by the servo motor ,pulling the wire net by the servo motor auto.

4.The reinforced steel bar mesh panel welding machine welding power comes from the air cylinders. It's easy to control the welding pressure .

5.The weft wire of wire mesh welding machine feeding from the multi hopper which capacity is more over ten times than the traditional hopper.

6.The reinforced steel bar mesh panel welding machine added the bear wire net and carry equipment that makes the working more convenience .

7.The welding part of wire mesh welding machine is used the springiness input wire trunking that makes the welding copper use for long time.

8.This reinforced steel bar mesh panel welding machine adopts synchronous control technique. The cent-control and welding time are composed of PLC program system. The input front-panel is touch screen , the operate is more intelligent and reasonable.

Features of Reinforced Steel Bar Mesh Panel Welding Machine:

1. Welding cylinder.

The welding cylinder is specially customized, with fast and stable action. The most important thing is to prolong the service life to a great extent.

All mechanical parts, pipes, bolts, fixtures and connecting devices are standard parts. We can easily provide mechanical accessories.

3. Adjust the mesh

The welding wire diameter range of the device is 6-12 mm, the mesh size is 100-300 mm, step-less adjustable. The maximum width of the welding wire mesh is 3000 mm (also according to customer requirements).

4. Alarm device

There is an alarm device on the welding host that can improve the safety level and reduce the failure rate. The greatest degree of assurance of the equipment running smoothly.

5. Servo motor

Welding system uses servo motor control, works accurately and use process does not produce sludge, has little effect on the environment. All key components are well-known brands, and the quality of the procurement system is in full accordance with ISO9001 standards. And comply with EU safety certification standards.

6. Smart Operation

System equipment can and desktop computers or notebook computers or workstations are connected. Easy operation. The greatest degree of raw material savings for customers. Improve production efficiency, and intelligent management.

Technical Parameters of Reinforced Steel Bar Mesh Panel Welding Machine:

| Model | DX-GWC3000B |

| Wire diameter | 6-12mm |

| Max.Weld wire diameter | 12+12mm |

| Mesh size | from 100*100mm to 250*250mm |

| Length of mesh panel | 3-12m |

| Number of welding electrode | 30 pcs |

| Welding transformer | 200KVA*30pcs |

| Pulling mesh way | By servo motor |

| Line wire type | Pre-cut |

| Cross wire type | Pre-cut |

| Control system | PLC and touch screen |

| Machine weight | 10T |

| Floor space | 25*6m |

| Power transformer | 300KVA |

| Production capacity | 35 tons at 10 hours |

Applications of Reinforced Steel Bar Mesh Panel Welding Machine:

The reinforcing mesh used in Bridges and highway to strengthen building strength and prevent engineering cracking.

Photos of Reinforced Steel Bar Mesh Panel Welding Machine:

![]()

![]()

![]()

![]()