-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

CE 2500mm Pre Cut 6mm Chicken Mesh Making Machine

| Place of Origin | China |

|---|---|

| Brand Name | DIXUN |

| Certification | CE |

| Model Number | DX-GWCD-2500D+ |

| Minimum Order Quantity | One set |

| Packaging Details | The Electric Welded Mesh Panel Welding Machine is nude packing. Need one 20 feet container to ship. |

| Delivery Time | 30 working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 6 sets per month |

| Product Name | Mesh Panel Welding Machine | Wire Diameter | 3-6mm |

|---|---|---|---|

| Mesh Width | Max 2500mm | Line Wire Space | 50-300mm |

| Cross Wire Space | 25-300mm | Line Wire Form | Pre-straighten And Pre-cut |

| Cross Wire Form | Pre-straighten And Pre-cut | Main Motor Power | 5.5kw |

| Power Transformer | 120KVA | Welding Transformer | 160KVA*8PCS |

| Highlight | 6mm Chicken Mesh Making Machine,2500mm Chicken Mesh Making Machine,CE fence making machine |

||

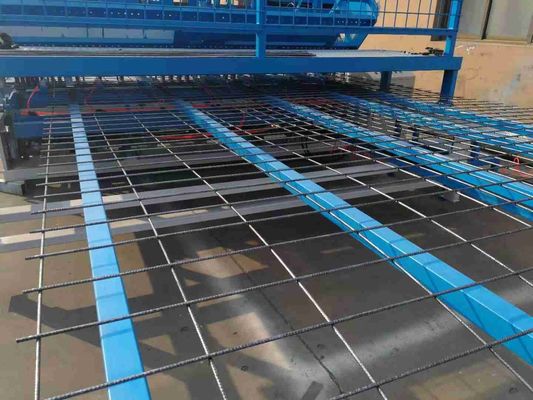

Welding Rebar 3-6mm Line Wire Pre-Cut Electric Welded Mesh Panel Welding Machine

Electric Welded Mesh Panel Welding Machine Introduction:

The electric welded mesh panel welding machine export to 30 countries for many years with advanced mesh welding technology experience, independent research and development of innovative devices. Transverse reinforcement raw material storage frame with funnel method, you can store a lot of raw materials. Easy handling, improve production efficiency and reduce labor costs. Reinforced length delivery process automatic control. Equipment to strengthen the damping process, effectively reducing noise. Welding wire diameter range of the device is 3-6mm, the mesh size is 50-200mm, stepless adjustable. The maximum width of the welding wire mesh is 2500mm (also according to customer requirements).

Electric Welded Mesh Panel Welding Machine Introduction Features:

1. CNC wheel-step design to provide high accurate mesh grid

2. Electrode lift system to extend electrode life

3. Line wire loop and balance system to ensure wire mesh accuracy.

4. Line wire vertical straightening system to provide high quality

5. Welding pressure steplessly adjust to apply multiple wire diameter

6. Line wire automatic put by from wire feeding car

7. System equipment can and desktop computers or notebook computers or workstations are connected. Easy operation. By raw material usage optimization system can achieve the ultimate. The greatest degree of raw material savings for customers. Improve production efficiency, provide more efficient, intelligent management.

Electric Welded Mesh Panel Welding Machine Technical Parameters:

| Model | DX-GWCD-2500+ | Wire diameter | 3.0-6.0mm |

| Line wire distance | 50-300mm | Cross wire distance | 25-300mm |

| Line wire feeding | By wire feeding car | Cross wire feeding | Pre-cut wire automatic feeding |

| Welding speed | 45-70 times per min | Rated power | 160KVA*8PCS |

| Mesh width | Max 2500mm | Welding points | 51PCS |

| Mesh length | Max 7m | Labor cost | 2 persons |

| Machine weight | 4.5T | Machine dimension | 9000*3300*1800mm |

| Control system | By PLC | Workshop size | 20*6m |

Electric Welded Mesh Panel Welding Machine Applications:

1. The steel wire mesh can be used as a floor heating and heat supply network, and laying on the ground, in this case, the construction site operation experience of a friend is no stranger to the operation, in fact, in many construction sites now, in the construction of buildings, generally adopts the integral casting method, laying on the cement and steel wire mesh in order to achieve better effect of casting, the advantage is that can make the ground of the casting, and to make buildings more durable.

2. The wire mesh is usually used in bridge building, and can be laid on the surface of the bridge, making stronger, Bridges and other structures are usually built in large buildings (such as bridge), steel wire mesh can be blended in cement in order to increase the toughness of the bridge deck on the surface, so that the bridge deck is more solid, more strong.

3. Steel wire mesh can also be used in coal mines, so as to play the role of support and protection of coal mines, coal mines using steel wire mesh mesh is usually greater than 6 mm, they are made of screw steel, with anti-slip effect.

4. Wire mesh can also be used for flood control and disaster relief and other places, of course, wire mesh can also be used in the breeding industry, as a simple guardrail used, so as to control the activities of chickens and ducks within a fixed range, can prevent chickens and ducks and other animals from running away, wire mesh in flood control and disaster relief, it can play a role in blocking heavy objects.

Electric Welded Mesh Panel Welding Machine Photos:

![]()

![]()

![]()