-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

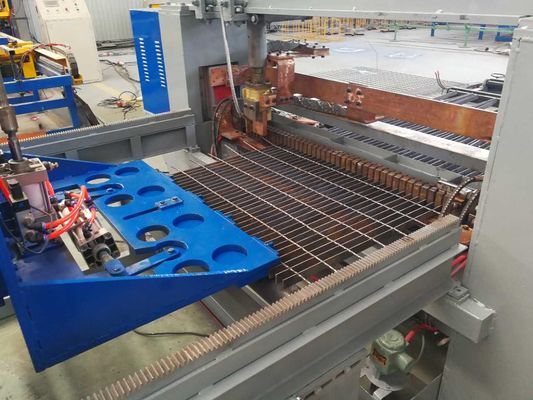

Hydraulic Mould Feed 30mm Steel And Iron Welding Machine

| Place of Origin | China |

|---|---|

| Brand Name | DIXUN |

| Certification | CE |

| Model Number | DX-SG-1200 |

| Minimum Order Quantity | One set |

| Packaging Details | The Serrated Steel Bar Grating Welding Machine is nude packing. Need 20 feet container. |

| Delivery Time | 30 working days |

| Payment Terms | L/C, T/T |

| Supply Ability | 5 sets per month |

| Product Name | Steel Grating Welding Machine | Applications | Power Plants, Refineries, Sewage Treatment Plants, Granaries, Chemical Plants, Highways, Airports And Wharves And Other Platforms, Walkways And Drainage Ditch Cover, Stairs Step, |

|---|---|---|---|

| Working Theory | Resistance Welding | Welding Mesh Width | Max 1200mm |

| Space Of Flat Bar | 30mm 40mm 50mm | Space Of Cross Bar | 50-160mm |

| Flat Bar Feed | By Hydraulic Mould Feed | Cross Bar Feed | By Manual |

| Steel Bar Grating Size | 1.2m*6m | Machine Weight | 4200kg |

| Machine Dimension | 16*2.5*1.6m | Electricity Transformer | 300kva |

| Highlight | 30mm Steel And Iron Welding Machine,Hydraulic Steel And Iron Welding Machine,1200mm steel grating machine |

||

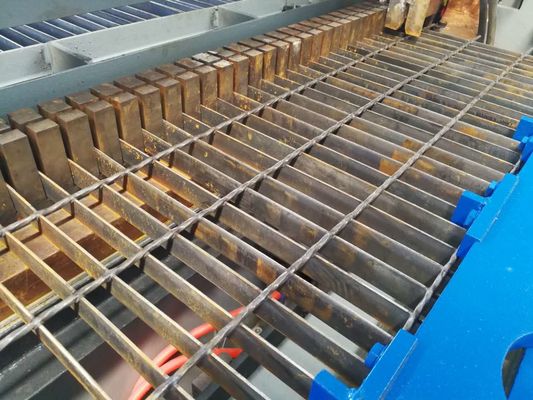

Flat Bar Space 30mm Stairs Step Serrated Steel Bar Grating Welding Machine

Serrated Steel Bar Grating Welding Machine Introduction:

Serrated steel bar grating welding machine is a concentration of electric, hydraulic, resistance welding, machinery, etc., as one of the large welding equipment.With compact structure, welding strong function, high degree of automation, product quality, convenient operation and maintenance, strong productivity, etc.Intermediate frequency welder frequency is 1000 hz, large output current density.The secondary loop output impedance is small, welding current, low dissipation electrodes directly connected to the rectifier circuit, greatly saves the energy required during welding.

Serrated Steel Bar Grating Welding Machine Features:

The machine include below: flat rack, hydraulic mold, servo stepper institutions, medium frequency transformer, host, intermediate frequency welding controller, control system.

The microcomputer controller

Products in Chinese liquid crystal microcomputer controller, the stable welding current, ensure the solder joints of beautiful, strong fastness.

In circulating cooling water system

The cooling circulating water with high water or water temperature automatic alarm., keep water temperature is less than 30 degrees, pure quality, so as not to reduce leakage and cooling water plugging.

Serrated steel bar grating welding machine advanced technology:

1. Control system : intelligent PLC(Mitsubishi or Panasonic)

2. Touch screen: Weinview (Taiwan)

3. Low-voltage apparatus :Schneider

4. Pneumatic components:Japan SMC, more stable

5. Mesh pulling :servo motor (Mitsubishi or Panasonic)

Serrated Steel Bar Grating Welding Machine Technical parameter

| Model | DX-SG-1200 | Capacity | 30--100 square meters/8hours |

| Falat bar range | 2.5*25mm--6*65mm | cross bar range | 5*5--8*8mm |

| Pitch of flat bar | 25--60mm | Pitch of cross bar | 50--160mm |

| Width of steel grating | 1200mm | Length of steel grating | 6m |

| Welding transformer | 250KVA*2 | Power supply | 160KVA |

| Dimension | 16*2.5*1.5m | Weight | 4.2T |

Serrated Steel Bar Grating Welding Machine Applications:

Serrated steel bar grating with high strength, light structure characteristics, widely used in petroleum chemical industry, power plant in recent years, water plant, sewage treatment works, municipal engineering, environmental sanitation in the areas of platform, walkway, pier, trench cover, manhole covers, ladders, fences, guardrail, etc.The product adopts the solid mesh pressure welding structure to make it high bearing, light structure and easy to operate.

Serrated Steel Bar Grating Welding Machine Photos:

![]()

![]()

![]()

![]()