-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

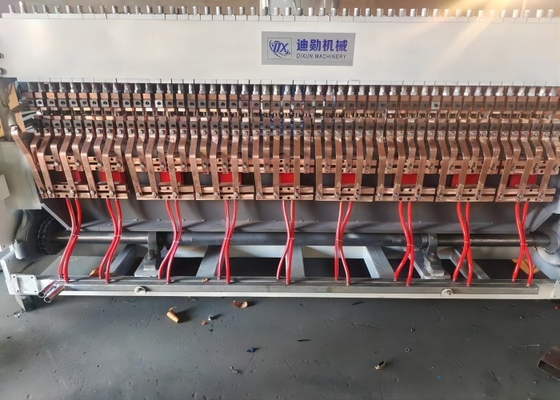

30mm Iron Plate Mesh Welded Wire Mesh Panel Machine 7-9kw/h High Efficiency

| Product Name | Welded Wire Mesh Panel Welding Machine | Hole Size | 50*50mm 100*100mm 150*150mm 200*200mm |

|---|---|---|---|

| Mesh Width | 1000mm.1200mm,1500mm,2000mm,2500mm | Wire Diameter | 4-8mm |

| Main Motor | 11kw | Mesh Length | 6m |

| Number Of Welding Electrode | 51PCS | Transformer Capacity | 160KVA |

| Size Of Welding Electrode | 30*30*18mm | Machine Weight | 5500kg |

| Highlight | Welded Wire Mesh Panel Machine 9kw/H,Welded Wire Mesh Panel Machine High Efficiency,fence mesh panel welding machine 9kw/H |

||

30mm Iron Plate Mesh Length 6m Welded Wire Mesh Panel Welding Machine

Introduction of Welded Wire Mesh Panel Welding Machine:

Welded Wire mesh panel welding machine adopts computer and PLC programming controller control, high degree of automation. Can be welded hot rolled rib, cold rolled rib, hot rolled round, cold rolled round and other materials, wide adaptability. According to the user's power consumption, the use of one or multiple welding, flexibility. Unit design is separable structure, convenient specification adjustment and maintenance. Transformer, thyristor, upper and lower electrodes and other welding systems adopt forced water cooling and flow protection device, unit can work reliably continuously. The pressure of welding pneumatic system is stepless and adjustable, which can quickly cope with the change of steel bar specifications. The welding pressure is uniform to ensure the quality of all solder joints. Welding standard pattern mesh, the upper and lower electrode positions do not need to adjust, do not take time to change the spacing price. Greatly increase real productivity.

Features of Wedled Wire Mesh Panel Welding Machine:

1. Mesh pulling mechanism: Japan Panasonic servo motor supporting planetary reducer drives pneumatic clamping mesh pulling device to ensure the stability of the system and the standard size of the welded mesh.Automatic reciprocating mesh drawing can realize the production of lengthening size mesh.

2. Water-cooled welding electrodes and a new type of special water-cooling transformer welding mesh with epoxy resin are adopted, which is smaller in size and higher in safety and reliability than traditional transformers.

3. Low-voltage electrical appliances are made of Schneider, well-known brands to ensure the efficient and stable operation of the equipment.

4. The wire mesh spot welding machine will stop working automatically if there is no cross wires in hopper device.

5. When there is malfunction on the machine, the PLC will alarm, which is convenient to adjust the machine.

6. The cross wire space adjustment adopts PLC micro-computer control, set on the touch screen.Very easy and convenient to operate.

The mesh pulling system is automatically calculated in cycle.No need manual setting. The mesh pulling car can be back to origin automatically after finishing the pulling mesh.

Technical Parameters of Welded Wire Mesh Panel Welding Machine:

| Model | DX-GWCD-2000 | DX-GWCD-2500 |

| Wire diameter | 4-8mm | 4-8mm |

| Longitudinal wire space | 50-250mm | 50-250mm |

| Cross wire space | 50-250mm | 50-250mm |

| Number of electrode | 41PCS | 51PCS |

| Transformer capacity | 160KVA*7PCS | 160KVA*9PCS |

| Main motor | 7.5KW | 11KW |

| Power supply | 120KVA | 120KVA |

| Floor space | 20*6m | 20*6m |

| Labor cost | 2 persons | 2 persons |

| Pulling mesh system | By servo motor | By servo motor |

| Longitudinal wire type | Pre-cut | Pre-cut |

| Cross wire type | Pre-cut | Pre-cut |

| Control system | PLC | PLC |

| Power consumption | 6-8kw/h | 7-9kw/h |

Applications of Welded Wire Mesh Panel Welding Machine:

Wire Mesh is mainly used in construction mesh, football field, railway, highway, bridge, building, residential areas and other guardrail mesh and shelves, storage cage.

Loading Photos of Welded Wire Mesh Panel Welding Machine:

![]()

![]()

Photos of Welded Wire Mesh Panel Welding Machine:

![]()

![]()