-

Wire Mesh Welding Machines

-

Reinforcing Mesh Welding Machine

-

Fence Mesh Welding Machine

-

Mesh Panel Welding Machine

-

Fixed Knot Fence Machine

-

Construction Mesh Welding Machine

-

Roll Mesh Welding Machine

-

Welded Wire Mesh Machine

-

Steel Grating Welding Machine

-

Razor Barbed Wire Machine

-

Chain Link Fence Making Machine

-

Steel Wire Drawing Machine

-

Wire Straightening And Cutting Machine

Servo Motor Pull Mesh Hopper Construction Mesh Welding Machine Load 1T

| Place of Origin | China |

|---|---|

| Brand Name | DIXUN |

| Certification | CE |

| Model Number | DX-2000B |

| Minimum Order Quantity | One set |

| Packaging Details | 1.main machine and accessory equipment will be packed with sketch film paper; 2.control cabinet and spare parts will be packed with the wooden box; 3.finally all the machines will be fixed with hornwoods and steel oil wire rope,ensure them stable and not |

| Delivery Time | 30 working days |

| Supply Ability | 6 sets per month |

Contact me for free samples and coupons.

WhatsAPP:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Construction Mesh Welding Equipment | Usage | Welding Fence Meshes |

|---|---|---|---|

| Weight | 4.5 T | Type | Welding Wire Machine |

| Welding Speed | 75-85 Times/min | Warranty | 2 Years |

| Mesh Width | Max. 2.5m | Control System | PLC+touch Screen |

| Welding Aperture | 100*100-300*300(mm) | Wire Diameter | 3.0-6.0mm |

| Line Wire Type | Coil Wire Feeding | Cross Wire Type | Pre-cut |

| Floor Space | 25*6m | Labor Cost | 1 Person |

| Highlight | Servo Motor Construction Mesh Welding Machine,1T Load Construction Mesh Welding Machine,Fence Construction Mesh Welding Machine |

||

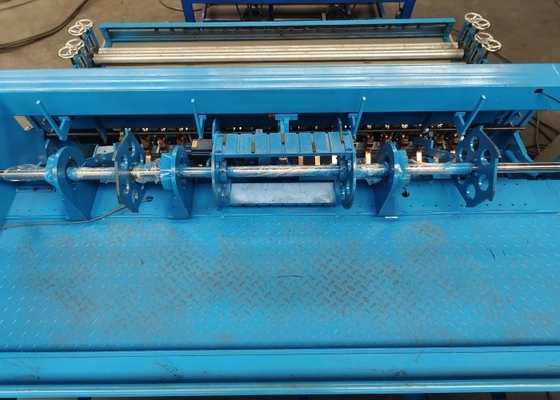

Servo Motor Pull Mesh Hopper Load 1T Construction Mesh Welding Equipment

Introduction of Construction Mesh Welding Equipment:

The construction mesh welding equipment is composed of pay-off frame, welding machine, cutting machine and electric control cabinet. The line wire is fed by 24 pay-off stands, and the cross wire is pre-straightened by wire straightening and cutting machine. The iron wire is welded into a mesh by the construction mesh welding equipment and then enters the mesh cutting machine and automatically cuts into the mesh. The construction mesh welding machine is mainly used for the resistance point (pressure) welding function of the line wire and the cross wire and the continuous mesh discharge. This construction mesh welding machine is mainly used to make wire diameter 3-6 low-carbon steel wire or galvanized wire.

1. Cross wire dithering device.

failures.

2. Cross wire feeding system moving device.

3. Cross wire positioning device.

4. Line wire straightening wheel.

5. Connecting copper block.

6. Electrode and copper base.

The electrode and copper base are all made of high chromium copper, which is a special alloy material with wear resistance and high temperature resistance. Increase the service life of the electrode.

7. Pull mesh system.

The mesh pulling system adopts servo motor, which can improve the accuracy of mesh size and make the mechanical operation more

smooth.

Technical Parameters of Construction Mesh Welding Equipment:

| Item | DX-1200A | DX-1600A | DX-2000B | DX-2500A |

| Number of Electrodes | 24 | 32 | 20 | 48 |

| Max.Mesh Width | 1200mm | 1600mm | 2000mm | 2500mm |

| Wire Diameter | 2.5-6.0mm | 2.5-6.0mm | 3.0-6.0mm | 3.0-6.0mm |

| Cross Wire Space | 50-250mm | 50-250mm | 100-250mm | 50-250mm |

| Line Wire Space | 50-250mm | 50-250mm | 50-250mm | 50-250mm |

| Finished Products Way | Panel Mesh | |||

| Pulling Mesh Way | Servo Motor | |||

| Electric Capacity | 125KVA*3 | 125KVA*4 | 125KVA*5 | 125KVA*6 |

| Welding Speed | 50-80t/min | 50-80t/min | 50-80t/min | 50-80t/min |

| Control System | PLC & Touch Screen | |||

Applications of Construction Mesh Welding Equipment:

The Panel Mesh is used in coal mine roof protection, tunnel, bridge construction, roadbed mesh, construction site construction materials.

Photos of Construction Mesh Welding Equipment:

![]()

![]()

![]()

![]()